- #MACH4 CNC SOFTWARE REQUIREMENTS INSTALL#

- #MACH4 CNC SOFTWARE REQUIREMENTS GENERATOR#

- #MACH4 CNC SOFTWARE REQUIREMENTS DRIVERS#

- #MACH4 CNC SOFTWARE REQUIREMENTS UPGRADE#

- #MACH4 CNC SOFTWARE REQUIREMENTS FULL#

– Asynchronous Motion (out of band axis) to control uncoordinated motion.

#MACH4 CNC SOFTWARE REQUIREMENTS GENERATOR#

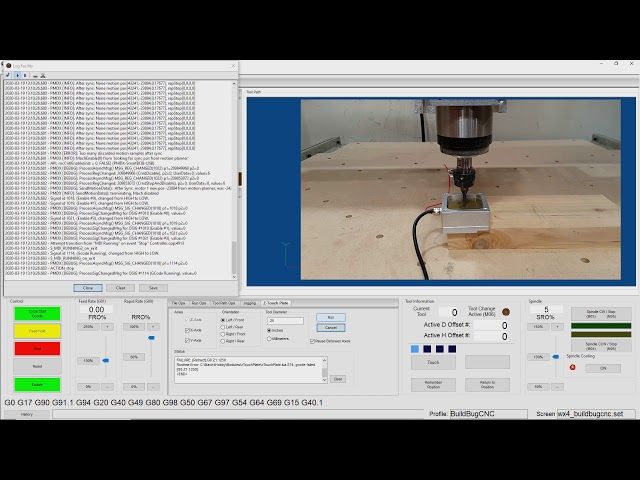

Higher quality manual pulse generator (MPG) = very smooth jogging and positioning without lag time. Improved Backlash Control & more accurate screw mapping = less jitter and more accurate cuts

Up to 100x faster response from button click to machine action. Mach3 software relied on the hardware plug-in software and complex buffering schemes to ensure accuracy and coordinated motion. Mach4’s core adapts to the speed (frequency) of the motion controllers attached.

#MACH4 CNC SOFTWARE REQUIREMENTS DRIVERS#

Motion Device Drivers (Plug Ins) have standard format = common level of functionality between components, less complexity, easier and less costly to troubleshoot and support.Īll motion control calculations are completed in the core. All Motion control calculated in the core = less dependence on hardware and associated software driver.

#MACH4 CNC SOFTWARE REQUIREMENTS FULL#

The core is a full featured ‘brain’ that ensures all input and output devices are coordinated with motion. Mach4 can control CNC machinery, PLC equipment, and robotics.

An appropriate external motion controller.Windows XP, Windows Vista, Windows 7, and Windows 8.PREFERRED: 32 or 64-bit Laptop or Desktop – Using an External Motion Controller

#MACH4 CNC SOFTWARE REQUIREMENTS UPGRADE#

If you upgrade or exchange your PC, it will be necessary to contact the distributor you purchased the license or create a new license yourself by logging into your account and using our website license maintenance feature. Each PC has a unique ID code and the license works in coordination with this code. IMPORTANT NOTE: The LICENSE will only work for the Computer for which you supplied the PC ID. To obtain your license key, Click the ‘copy ID to Clipboard’ button in the ‘about’ dialog box when running the software in demo mode and paste this ID number in the appropriate location on the website when purchasing your license. You must have this exact PC code from the actual PC you wish to license and generate G-code. Use the ‘About’ screen, accessed by the ‘Help’ menu to get the PC code. The license is linked to a specific PC, requiring a different code for each PC. Additional licenses can be created after the initial purchase from within your account. Use the PC ID code from the Help/About screen at checkout to license this single computer.Run the demo and go to the Help/about screen in Mach4.

#MACH4 CNC SOFTWARE REQUIREMENTS INSTALL#

This feature is available only on the DSPMC 7763M version as analog inputs are required.ħ737 Board: The pn7737 Differential Step/Direction and Encoder Board allows access to the Step/Direction and more Encoder channels and allows a simple plug-and-play setup (with any standard RJ45/Ethernet cable) when used in tandem with a Drive Interface Board (EPx-DIB) for Maxsine AC Servo Drives.ħ535 Board: The I/O Termination board ( 7535P or 7535N) provides additional optically isolated digital I/O. It allows the DSPMC to read an analog input at an ultra-fast scan rate and activate a digital output at the moment the voltage reading goes above or below a configured threshold. Advanced and production applications can also benefit from these add-ons:ĭSPMC-MACRO : This software feature allows the user to write custom programs (In C language)which can be downloaded to the controller for fast execution.ĭSPMC-SNT : This software feature is a specialized tool for EDM Machines.

0 kommentar(er)

0 kommentar(er)